PETWood builds a connected circular economy that empowers communities, transforms waste into high-value materials, and partners with sustainable brands to drive measurable social and environmental impact.

Community Empowerment and Waste Collection

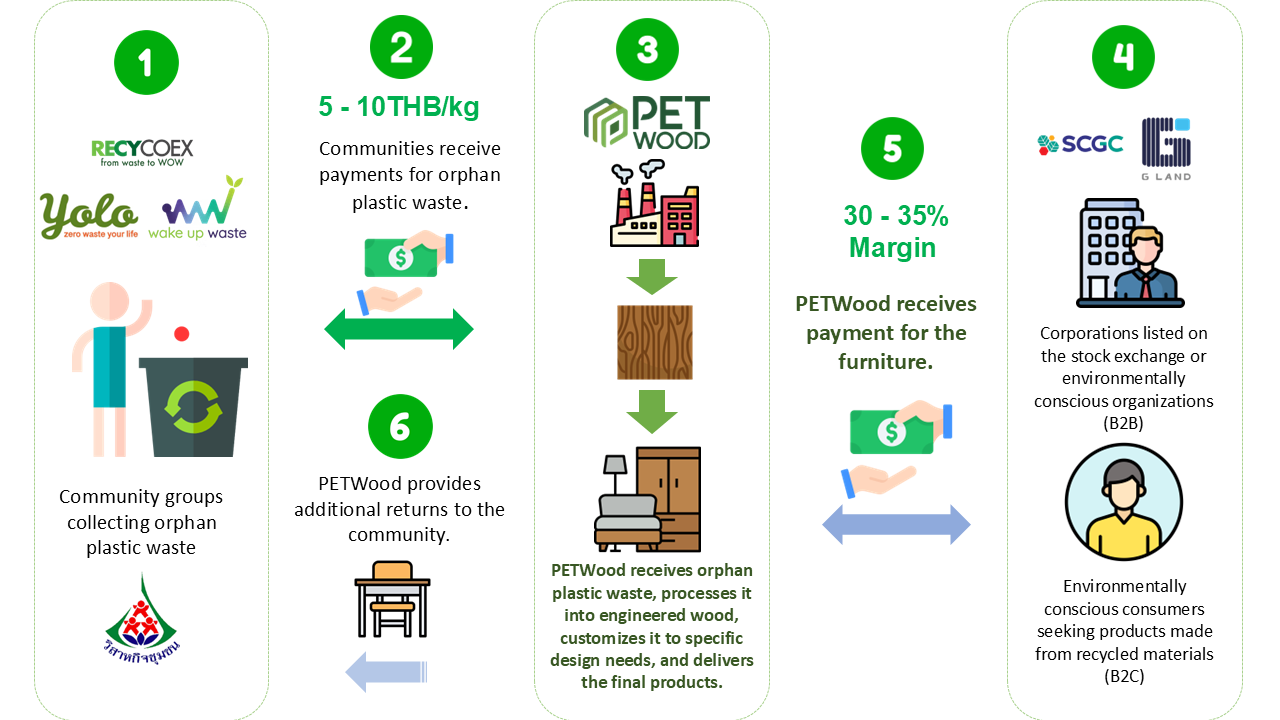

PETWood begins at the grassroots. We work closely with community partners like RecyCoex, Yolo, and Wake Up Waste, as well as informal waste pickers and recycling groups. These local collectors gather orphan plastic waste—the most difficult type to recycle—and receive fair payments between 5–10 THB per kilogram.

This model ensures that income flows directly to women, youth, and underrepresented community members through GEDSI (Gender Equality, Disability and Social Inclusion) programs, turning waste recovery into a stable livelihood.

Innovation in Circular Manufacturing

After collection, PETWood processes the plastic waste using low-energy thermo-compression technology, converting it into durable composite panels known as PETWood Boards. Each panel is customizable, waterproof, termite-resistant, and built to last three times longer than MDF or plywood.

From these engineered panels, PETWood designs and manufactures high-quality furniture—benches, tables, and boards—used in schools, hotels, and green buildings nationwide. Every piece of furniture tells the story of transformation—from waste to design, from local hands to circular innovation.

Corporate and Market Collaboration

We partner with SCGC, G Land, and other corporations listed on the stock exchange who are committed to ESG and circular economy goals. PETWood provides sustainable products for offices, hotels, and communities, meeting both LEED and Green Hotel Certification standards.

At the same time, we serve eco-conscious consumers (B2C) who seek to purchase responsibly produced furniture that aligns with a carbon-neutral lifestyle. This dual B2B and B2C model strengthens both market reach and social impact.

Circular Value Return to Communities

Unlike traditional business models, PETWood shares its success back with the people who make it possible. With an operating margin of 30–35%, part of the revenue is reinvested into community initiatives—upgrading collection centers, providing safety gear and recycling equipment, and creating local innovation workshops.

This system builds a self-sustaining circular economy where economic, social, and environmental benefits continually flow back to the community.

With a 30–35% operating margin, PETWood reinvests part of its profits back into local recycling programs — supporting waste pickers, upgrading collection centers, and funding GEDSI initiatives.

This creates a shared-value loop where communities, customers, and the planet all benefit.